|

Tube Forming & Tube Processing Capabilities

PARTIAL LIST

|

TUBE “BENDING“

- BEND / FORM SMALL DIAMETERS STARTING AT 1/16″ OUTSIDE DIAMETER.

- CAPABLEOF TIGHT RADIUS BENDING, DOWN TO “1D” BENDS (1 TUBE DIAMETER BENDS).

|

TUBE “POST-BENDING AND ASSEMBLY“

- APPLICATION / INSTALLATION OF MECHANICAL

- BRAZED, SWAGED

- WELDED FITTINGS

- PLATING

- SPECIAL COATINGS

- SPECIAL CLEANING

- PART IDENTIFICATION

- KITTING WITH OTHER COMPONENTS

- TESTING

- CUSTOM LABELING

- BAR-CODING

|

TUBE “END FINISHING TYPES“

- SWAGING

- BEADING

- FLANGING

- SINGLE FLARING

- DOUBLE FLARING

- EXPANDING

- SQUARING

- CUTTING

- FACING

- REDUCING

- WELDING

- NOTCHING

|

TUBE “END TERMINATION FITTINGS“

- PERMASWAGE

- CRYOGENIC

- COMPRESSION

- FLARED

- BRAZED

- AND WELDED FITTINGS

|

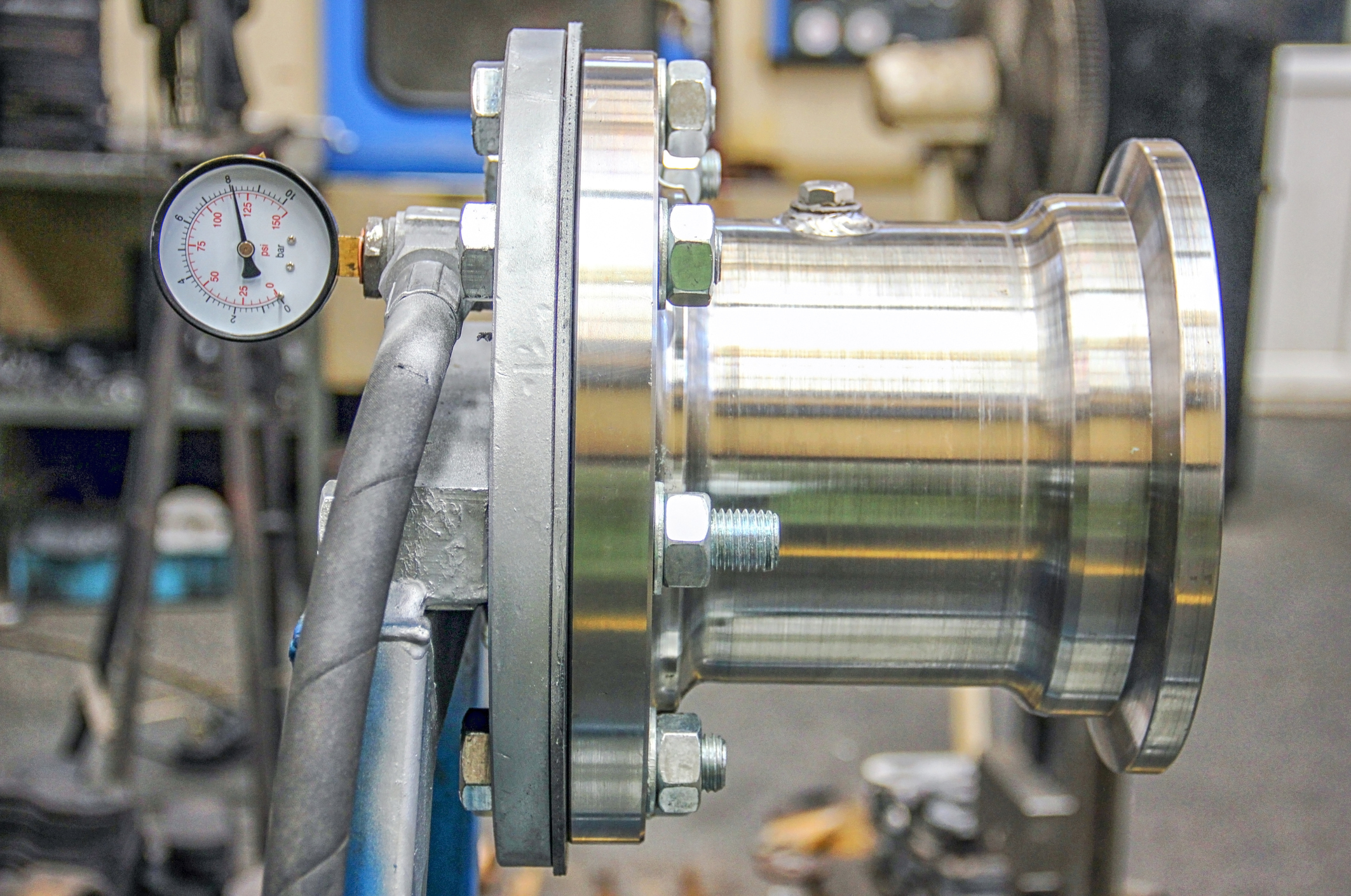

TUBE ASSEMBLY “SPECIAL PROCESSES”

- TUBE ASSEMBLY LEAK TESTING.

- LOW / MEDIUM PRESSURE PROOF TESTING USING AIR MEDIA.

- HIGH PRESSURE PROOF AND BURST TESTING USING HYDROSTATIC MEDIA.

- FUSION WELDING – NADCAP ACCREDITED WELDING

|

TUBE ASSEMBLY “INSPECTION“

- TUBE INSPECTION USING LASER VECTOR MEASUREMENT ANALYZER.

- ENGINEERING DATA TYPES: “LRA”, “XYZ”, “CAD/DXF/CATIA/IGES” OR “PAPER” DATA.

|